Understanding Excavator Components

Overview of Excavator Parts – Detailed overview of main excavator components

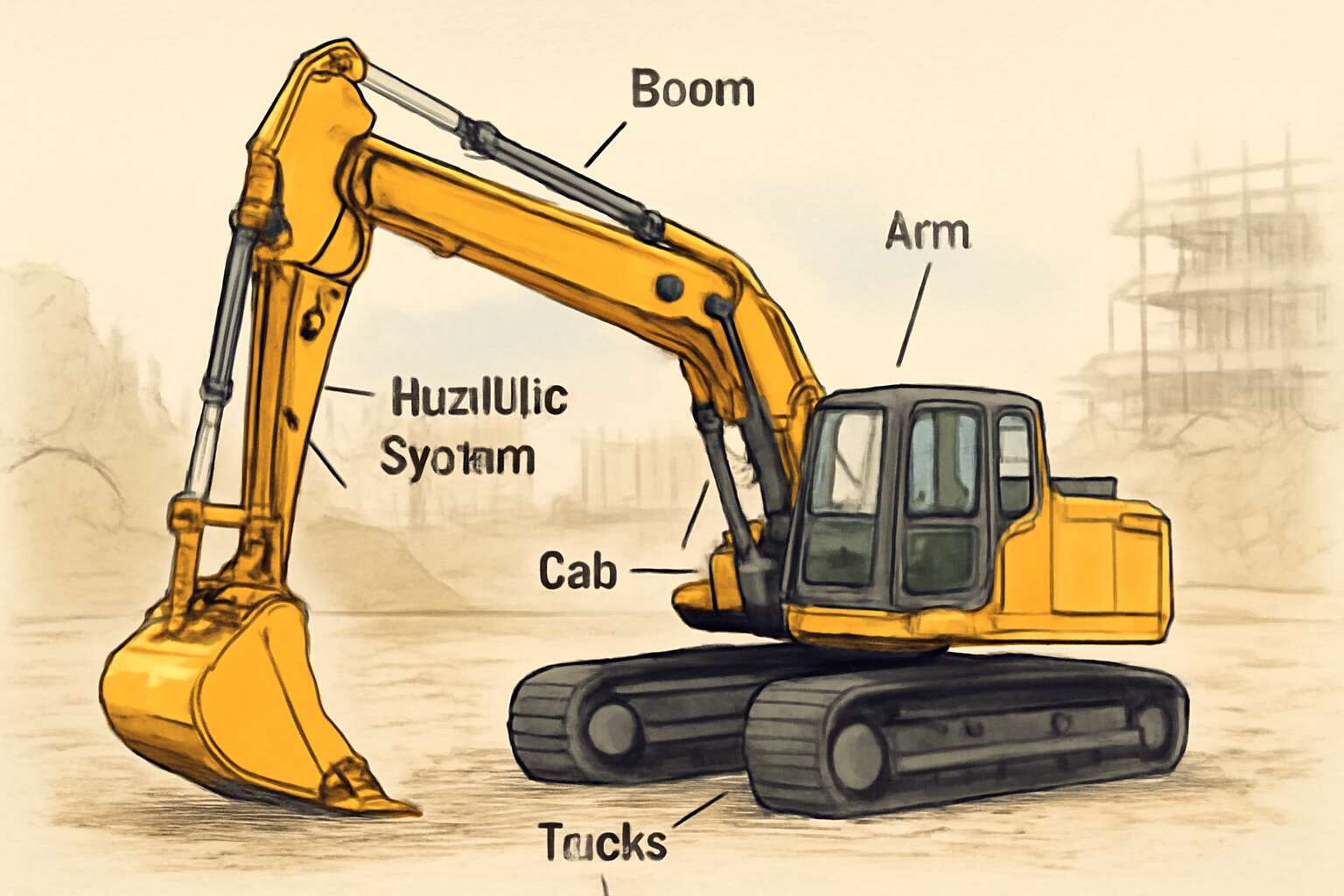

Understanding excavator components is essential for anyone looking to optimise their construction operations. An accurate excavator diagram offers a detailed visual representation of the machine’s main parts, making complex machinery easier to comprehend. These diagrams are invaluable for troubleshooting, maintenance, and ensuring safety standards are met on-site.

At the heart of an excavator are several key components that work together seamlessly. The boom, arm, and bucket form the primary working elements, while the undercarriage provides stability and mobility. Additionally, the hydraulic system powers the movement of these parts, making it the lifeblood of the excavator.

A typical excavator diagram highlights these parts clearly, often accompanied by labels and cross-sections to illustrate how they interact. Recognising the function of each component can significantly extend the lifespan of your equipment and improve operational efficiency. Whether you’re a seasoned operator or new to the field, familiarising yourself with an excavator diagram is a step towards smarter, safer machine handling.

Tracking and Mobility System – Description of the undercarriage and tracks

In the labyrinthine world of excavator operation, few components invite as much fascination as the undercarriage and its tracks. These humble yet vital elements are the unsung heroes of mobility and tracking, often overlooked in favour of the more glamorous boom or bucket. An accurate excavator diagram vividly illustrates how these parts form the foundation of stability and manoeuvrability, ensuring that the machine functions seamlessly across rugged terrains.

The undercarriage, comprising the track frame, rollers, and sprockets, acts as the machine’s legs, providing a sturdy base that withstands the rigours of tough construction sites. The tracks themselves distribute the excavator’s weight evenly, preventing unwanted ground disturbance and enabling smooth navigation through challenging environments. Recognising the intricate relationship between these components, often detailed in an excavator diagram, reveals the complex harmony required to keep the machine on its feet—literally!

For those seeking to optimise excavator tracking and mobility, understanding how these parts work together is essential. By appreciating the nuances of the excavator diagram, operators and technicians can better diagnose issues, enhance efficiency, and prolong equipment lifespan—an investment in machinery that truly pays dividends. After all, a well-designed undercarriage isn’t just about mobility; it’s about mastery over the terrain itself.

Upper Structure and Cabin – Details about the operator cab and upper frame

Understanding the excavator components of the upper structure and cabin is crucial for appreciating how these machines operate with precision and safety. The operator cab, often considered the nerve centre, provides the essential environment for controlling all functions. It’s designed with ergonomics in mind, ensuring operators can work comfortably for long hours while maintaining focus on demanding tasks.

The upper frame connects the cab to the rest of the excavator, supporting the boom, arm, and attachment mechanisms. This section must withstand significant stress, especially during heavy lifting or prolonged use. An accurate excavator diagram vividly illustrates how the upper structure integrates these elements seamlessly, forming a sturdy yet flexible platform for operation. To facilitate maintenance and repairs, many diagrams highlight key components such as hydraulic controls, safety features, and visibility enhancements.

In essence, the upper structure and cab are the human-machine interface. Their design and integrity directly impact operational efficiency and safety. Recognising how these parts fit into the overall excavator diagram offers vital insights into the machine’s functionality, making it easier for technicians and operators alike to diagnose issues and optimise performance. Truly, mastering the details of the excavator diagram can turn a good operator into an effective one—after all, understanding the machine’s core is the first step to mastering it.

Hydraulic System Fundamentals – Explanation of hydraulic components and their functions

Within the intricate tapestry of an excavator diagram lies the heartbeat of this mighty machine — its hydraulic system. These components work in harmony, transforming fluid into formidable force, enabling the excavator to dig, lift, and manoeuvre with unparalleled precision. At the core are hydraulic pumps, which generate the pressure necessary to energise the system, while hydraulic cylinders translate this pressure into linear motion, orchestrating the movement of the boom, arm, and bucket.

Understanding the fundamental hydraulic components is akin to mastering the secret arts of construction magic. Valves regulate flow, directing the hydraulic fluid exactly where it’s needed, ensuring smooth and controlled operations. The hydraulic motor then converts this pressurised fluid back into rotational force, powering the swing mechanism of the excavator. A well-crafted excavator diagram vividly illustrates these vital parts, revealing how they interlock like a finely tuned clockwork ensemble, all designed to withstand immense stress while maintaining safety and efficiency.

Boom, Arm, and Bucket – Description of primary attachments and their roles

When you gaze upon an excavator diagram, what you’re really seeing is a blueprint of brute force and engineering elegance rolled into one. Central to this mechanical marvel are three primary attachments: the boom, arm, and bucket. These components form the trifecta of digging prowess, each with a distinct role in the excavation process.

The boom is the sturdy, towering backbone—think of it as the excavator’s armoured ribcage—providing height and reach. Attached to it is the arm, a versatile link that extends and retracts, allowing the operator to position the bucket with surgical precision. The bucket itself is the tool of choice for scooping, digging, or hauling—essentially the excavator’s chisel and scoop combined into one multifunctional marvel.

- The boom offers the vertical lift, anchoring the entire operation.

- The arm provides the dynamic extension, reaching into the depths of the worksite.

- The bucket handles the gritty realisation of the task—digging, loading, and material handling—making it the unsung hero of the excavator diagram.

Understanding these primary attachments is like decoding the secret language of construction machinery, revealing how each part interlocks seamlessly to handle the most arduous tasks with unwavering efficiency. Excavator diagrams serve as visual guides, illustrating how these components work in concert to turn fluid power into earth-shattering force—truly a marvel of modern engineering ingenuity!

Interpreting an Excavator Diagram

Diagram Types and Formats – Different styles of excavator diagrams (technical, simplified)

Understanding an excavator diagram is more than just reading lines and symbols; it’s about deciphering the silent language of machinery. Different styles of excavator diagrams—ranging from technical schematics to simplified illustrations—serve distinct purposes. Technical diagrams, with their intricate detail, cater to engineers and professionals who need precision, highlighting every hydraulic line and component with exactitude. Conversely, simplified diagrams distill complex systems into easy-to-understand visuals, making them accessible for new operators or training purposes.

The format of an excavator diagram can significantly influence its effectiveness. Some visuals adopt a flat, two-dimensional style, emphasising clarity over detail, while others employ three-dimensional perspectives, offering depth and spatial understanding. Recognising these variations allows one to interpret the diagram more intuitively, bridging the gap between abstract symbols and real-world machinery. After all, an excavator diagram is not merely a tool—it’s a window into the machine’s soul, revealing its inner workings in a language both universal and precise.

Reading Labels and Symbols – How to understand common diagram annotations

Interpreting an excavator diagram requires more than just recognising lines and symbols; it’s about understanding the language that machinery speaks. Labels and symbols on these diagrams serve as shortcuts, conveying crucial information about the machine’s operation and configuration. For instance, hydraulic lines are often marked with specific symbols indicating flow direction or pressure, which helps operators and engineers grasp how fluid moves within the system.

Common annotations include colour codes, arrow directions, and abbreviations that identify components like valves, cylinders, and pumps. To get a clear picture, look for standard symbols such as a circle for a hydraulic pump or a zigzag line representing a hydraulic hose. Recognising these annotations transforms a confusing mess of lines into a coherent story of how the excavator functions.

In many cases, understanding an excavator diagram also involves deciphering labels that specify pressure levels, component ratings, or operational states. An effective way to approach this is to follow the flow path from the hydraulic pump to the attachment, noting each symbol and its role. This methodical reading of the diagram ensures you truly understand how the machine’s hydraulic system and other vital parts work together—making the excavator diagram not just a visual aid, but a tool for deeper insight into one of the most complex pieces of construction machinery.

Color Coding and Legends – Using color and legends for component identification

In the intricate ballet of excavator operation, colour coding and legends act as the choreographer’s notes—guiding viewers through a complex dance of hydraulic lines, structural components, and safety zones. An excavator diagram employs a palette of colours to distinguish vital parts swiftly, turning what could be a muddled mess into a visual symphony of clarity. For instance, red often signals high-pressure lines, while blue may denote return flows, allowing even the most novice observer to follow the hydraulic choreography with ease.

Legends serve as the Rosetta Stone of these diagrams, translating abstract symbols and hues into meaningful insights. Recognising that a green line might indicate auxiliary functions or that a yellow label highlights a critical safety feature can save time—and potentially prevent costly errors. To aid navigation, many diagrams incorporate a key that clarifies these colour codes and symbols, transforming the complicated into the comprehensible. This harmonious utilisation of colour and legend ensures the excavator diagram is not merely a technical image but a powerful tool for understanding the lifeblood of heavy machinery.

Understanding Hydraulic Flow Paths – Diagram indications of hydraulic fluid movement

In the shadowed realm of heavy machinery, understanding the labyrinthine pathways of hydraulic flow within an excavator diagram reveals a hidden language—an intricate dance of fluid that breathes life into the beast. These diagrams map the silent currents coursing through high-pressure lines and return flows, unveiling the unseen arteries that power each movement. As you trace these paths, you begin to decipher the whispered secrets of hydraulic fluid movement, revealing how the mighty arm extends or retracts with precision and grace.

To truly interpret an excavator diagram’s hydraulic pathways, one must follow the flow from the pump through various valves and cylinders, each segment a vital chapter in the machinery’s story. Recognising the directional arrows and symbols embedded within the diagram enhances comprehension, transforming abstract lines into a vivid narrative of power and control. By visualising these flow paths, an observer can anticipate the machine’s behaviour, unlocking a deeper understanding of its operation amidst the shadows of steel and hydraulic might.

Benefits of Using Excavator Diagrams

Maintenance and Troubleshooting – How diagrams assist in repairs and diagnostics

In the shadowed corridors of heavy machinery, where steel giants breathe and pulse with hidden life, the excavator diagram becomes a vital map for those daring enough to decipher its cryptic symbols. These diagrams serve as the silent guardians of maintenance, unveiling the intricate web of hydraulic pathways and structural secrets that power the beast. When a machine falters, the excavator diagram offers a lantern to illuminate the unseen faults lurking beneath the surface.

By studying these visual blueprints, technicians gain an almost supernatural clarity—pinpointing leaks, worn components, or misalignments with precision. The diagram’s clarity cuts through the chaos, transforming complex repairs into manageable puzzles. It’s an essential tool in troubleshooting, transforming vague symptoms into clear diagnoses. In this realm, where every misstep can spell disaster, the excavator diagram becomes an indispensable guide—an arcane script that reveals the machinery’s true nature and ensures its enduring strength amidst the shadows.

Assembly and Manufacturing – Role of diagrams in construction and assembly processes

In the grand theatre of construction, where steel colossi rise and fall like titanic sculptures, the excavator diagram acts as the silent architect’s blueprint—an essential instrument in transforming raw concepts into towering realities. These detailed diagrams serve as a vital nexus between design and execution, guiding assembly with precision akin to a maestro’s baton. By translating complex engineering into visual harmony, they streamline the manufacturing process, ensuring each component fits seamlessly within the intricate symphony of the machinery.

Moreover, the role of excavator diagrams in construction cannot be overstated. They facilitate clarity in the assembly process, reducing the risk of errors and accelerating project timelines. For builders and engineers alike, these visual guides act as navigational stars, illuminating the path through the labyrinth of parts and connections. From the placement of hydraulic lines to the alignment of structural elements, every detail is etched with purpose, transforming abstract schematics into tangible, functioning marvels.

Embracing these diagrams means embracing efficiency, precision, and safety—cornerstones in the creation of heavy machinery that endures the relentless demands of the industry. Assembling an excavator is no longer a leap into the unknown but a calculated journey mapped meticulously by these invaluable visual tools.

Operator Training – Using diagrams for effective operator education

In the realm of heavy machinery, where precision and safety are paramount, the role of an excavator diagram in operator training cannot be overstated. These visual masterpieces serve as a bridge between technical complexity and practical mastery, transforming abstract schematics into accessible learning tools. When operators familiarise themselves with detailed excavator diagrams, they gain a clearer understanding of the machine’s inner workings, fostering confidence and competence in manoeuvring such formidable equipment.

By utilising excavator diagrams during training sessions, instructors can illustrate the flow of hydraulic systems, the articulation of the boom and arm, and the intricacies of control mechanisms with clarity. This visual approach enhances retention and reduces the likelihood of errors, especially in high-stakes environments. Furthermore, these diagrams help operators anticipate potential issues, recognise component function, and develop an intuitive sense of the machinery’s behaviour under different loads and conditions.

The benefits extend beyond mere comprehension; incorporating excavator diagrams into operator education elevates safety standards and operational efficiency. With a comprehensive understanding of the machine’s anatomy, operators can perform precise manoeuvres, troubleshoot minor faults, and maintain the equipment effectively—turning complex machinery into a well-orchestrated symphony of mechanical harmony.

Parts Replacement and Upgrades – Identifying parts for replacement and upgrades

In the shadowed corridors of heavy machinery, where every bolt and hydraulic valve whispers a secret, the excavator diagram emerges as a vital map for those who dare to navigate its labyrinth. These intricate visual guides unlock the hidden language of the machine, revealing the delicate dance of parts that keep the beast alive. When it comes to parts replacement and upgrades, an excavator diagram is the key to unlocking precision and avoiding catastrophe.

By deciphering the symbols and labels etched into these diagrams, operators and technicians can identify specific components that need attention—be it a worn-out hydraulic hose or an antiquated arm assembly. Recognising the exact location and function of each part prevents destructive guesswork and preserves the integrity of the machine. For upgrades, the excavator diagram offers a blueprint for seamless integration, ensuring new parts mesh perfectly with existing systems without disturbing the fragile equilibrium of the machinery.

Understanding the layout of hydraulic flow paths and structural elements through these diagrams transforms the repair process from guesswork into a meticulous craft. This clarity not only expedites repairs but also enhances safety, allowing the operator to anticipate potential failures before they manifest in catastrophic failure. As the dark symphony of machinery hums in the background, the excavator diagram remains an invaluable tool—illuminating the path to longevity and mastery in the realm of heavy equipment.

Creating and Customizing Excavator Diagrams

Tools and Software for Diagram Design – Popular CAD and diagram tools used

Creating and customizing excavator diagrams requires precision tools and specialised software to translate complex machinery into clear visual representations. Modern CAD (Computer-Aided Design) programs such as AutoCAD and SolidWorks are popular choices, offering engineers and designers the ability to craft detailed, scalable excavator diagrams with ease. These tools provide an array of features for customising components, adjusting angles, and annotating diagrams with labels and symbols for enhanced clarity.

For those seeking streamlined options, dedicated diagram software like Lucidchart or Microsoft Visio can also facilitate the creation of simplified excavator diagrams, ideal for training or simplified visual communication. These platforms often support importing existing CAD files, enabling seamless integration of detailed technical schematics into broader project workflows.

Utilising these tools not only ensures accuracy but also empowers professionals to tailor excavator diagrams to specific project needs—whether for maintenance, assembly, or operator training—transforming complex machinery into an understandable visual language.

Best Practices for Accurate Representation – Tips for drawing clear and precise diagrams

Creating and customizing an excavator diagram demands a meticulous touch—an understanding that every line, angle, and label conveys a part of the machinery’s story. To achieve truly accurate representations, it’s essential to embrace best practices that prioritise clarity and precision. Start with a clear outline of the main components, ensuring each element is proportionate and logically positioned. When drawing, use consistent line weights and avoid clutter; this preserves the diagram’s readability even when scaled down or viewed from afar.

Incorporating colour coding and legends can transform a complex excavator diagram into an intuitive visual language. This not only aids in quick identification but also reduces misinterpretation—crucial when precision matters most. Remember, the goal is to foster understanding, not confusion. By paying close attention to detail and employing thoughtful visual cues, you create a tool that transcends mere technicality—becoming an instrument of clarity in a world often muddled by complexity.

Integrating Diagrams with Maintenance Manuals – Linking diagrams to operational documentation

Creating and customising an excavator diagram is a meticulous process that bridges the gap between technical precision and user-friendly clarity. When integrating these diagrams with maintenance manuals, it’s vital to establish seamless links that enhance understanding rather than complicate it. Clear visual connections allow operators and technicians to quickly pinpoint components, making troubleshooting and repairs more efficient.

Incorporating diagrams into operational documentation isn’t just about adding images; it’s about crafting a cohesive narrative that guides users through complex machinery with confidence. For instance, using consistent symbols and colour-coded labels within your excavator diagram can drastically reduce misinterpretation. This thoughtful approach transforms a simple technical drawing into a practical tool—an essential part of the maintenance and operational workflow.

Common Features in Excavator Diagrams

Dynamic vs. Static Diagrams – Differences and applications

Understanding the nuances between dynamic and static excavator diagrams reveals much about how these powerful machines operate and are maintained. While static diagrams offer a fixed, detailed snapshot of the excavator’s components, dynamic diagrams breathe life into the machinery, illustrating fluid movements and hydraulic flow paths in real-time. This distinction is crucial, especially when troubleshooting or training operators, as each type serves distinct functions.

Static excavator diagrams are typically employed in technical manuals, providing a clear, colour-coded overview of parts and their relationships. Conversely, dynamic diagrams find their strength in simulation software or live diagnostics, offering an interactive experience that demonstrates hydraulic flow paths and component interactions. Both types of excavator diagrams are invaluable in different scenarios—one for precise component identification and the other for understanding operational workflows—highlighting their importance in construction, repair, and operator education.

3D vs. 2D Diagrams – Advantages of different visualizations

In the realm of heavy machinery, visualisation is everything. An excavator diagram isn’t just a schematic; it’s a gateway to understanding the intricate dance of components that make these giants move. When choosing between 3D and 2D diagrams, recognising their unique features can unlock new levels of operational insight.

3D excavator diagrams offer a lifelike perspective, capturing the machine’s complex geometry with depth and realism. This visualisation makes it easier to grasp spatial relationships and recognise potential interference points during assembly or maintenance. Meanwhile, 2D diagrams focus on clarity and simplicity, providing precise, colour-coded views of individual parts and hydraulic flow paths. They are particularly useful for quick reference and detailed troubleshooting.

Both types of excavator diagrams serve vital roles—whether aiding in parts replacement or enhancing operator training. The choice often hinges on the task at hand and the level of detail required, making understanding their advantages essential for anyone working with these formidable machines.

Annotated Diagrams – Use of callouts and notes for clarity

In the intricate ballet of heavy machinery, clarity is paramount. An excavator diagram isn’t merely a collection of lines and symbols; it is a visual symphony that unravels the complexity of this magnificent machine. Common features in excavator diagrams often include meticulously annotated callouts and notes, which serve as guiding stars for engineers and operators alike. These annotations illuminate the function and placement of each component, creating a lucid map that transcends mere technicality.

Using well-placed callouts, an excavator diagram can succinctly identify vital parts, hydraulic flow paths, and critical maintenance points. This ensures that even when faced with the most daunting troubleshooting challenge, clarity remains within reach. Furthermore, legends and colour coding enhance comprehension, transforming a dense schematic into an accessible reference. In every line and label, there is an invitation to understand the machine’s heartbeat, making the excavator diagram an indispensable tool in the quest for operational mastery and safety.

FAQ About Excavator Diagrams

What Information Can I Find on an Excavator Diagram? – Details about components, hydraulics, and assembly

An excavator diagram offers a comprehensive window into the complex world of heavy machinery. It’s more than just a visual; it’s a detailed blueprint revealing the intricate relationship between components. When you examine an excavator diagram, you can identify key parts such as the hydraulic system, engine placement, and the structure of the arm and boom. This knowledge is invaluable for maintenance, repairs, and upgrades.

What information can I find on an excavator diagram? Quite a lot, actually! It typically includes labels for hydraulic flow paths, assembly points, and the layout of control systems. These diagrams also show how different components connect and interact, which is essential for troubleshooting issues or planning modifications. For instance, understanding the hydraulic flow paths helps operators and technicians optimise performance and diagnose faults quickly.

Whether you’re a seasoned operator or a maintenance professional, a detailed excavator diagram enhances your understanding of this essential construction equipment. It’s a vital tool that bridges the gap between technical manuals and real-world application, ensuring efficient operation and effective repairs. Plus, the colour coding and legends used in these diagrams simplify complex information, making it easier to interpret and act upon.

Are There Standard Symbols Used in Diagrams? – Explanation of standard conventions

In the world of heavy machinery, a well-constructed excavator diagram is akin to a detailed map guiding professionals through a labyrinth of complex components. But are there standard symbols used in these diagrams? Absolutely. Consistency in symbols ensures that both seasoned technicians and newcomers can interpret the excavator diagram accurately, saving valuable time during maintenance and repairs. These standard conventions often include specific icons for hydraulic lines, control levers, and structural parts, all designed to streamline understanding across different models and manufacturers.

Understanding these symbols is crucial. For instance, hydraulic flow paths are typically represented by arrows, indicating the direction of fluid movement—an essential detail when troubleshooting or planning upgrades. An organised excavator diagram employs colour coding and legends to clarify which parts are active, under pressure, or in need of inspection. This visual language transforms a potentially overwhelming schematic into an accessible, practical tool that enhances operational safety and efficiency.

By familiarising oneself with the standard symbols and conventions, operators and maintenance professionals can swiftly decipher the excavator diagram, making diagnostics more precise and repairs more effective. After all, clarity in diagrams isn’t just about aesthetics; it’s about empowering accurate decision-making in the demanding environment of construction sites.

How Do I Read a Hydraulic Diagram? – Step-by-step guide to understanding hydraulic flow

In the intricate ballet of construction machinery, the excavator diagram serves as both the score and the map—a visual symphony that deciphers the silent language of heavy engineering. When faced with a hydraulic diagram, many wonder how to read its complex flow of energy and fluid. The secret lies in understanding the choreography of hydraulic flow paths, where arrows dance across the schematic, revealing the direction of hydraulic fluid as it journeys through valves, cylinders, and pumps. These arrows aren’t just symbols; they are the pulse points of the excavator’s vitality.

To unravel this hydraulic narrative, start with tracing each arrow from its source—typically the hydraulic pump—through the system’s arteries. Observe the legends and colour coding that distinguish active lines from those under pressure. An ordered approach is helpful:

- Identify the hydraulic pump on the excavator diagram.

- Follow the arrows to see where hydraulic fluid flows during operation.

- Note the symbols for control valves, cylinders, and motors.

- Pay attention to pressure indicators and return lines, often marked with specific annotations.

By visualising each step, a technician transforms a static schematic into a dynamic understanding of how the excavator’s hydraulic system breathes and moves. It’s a dance of precision, where every symbol and line guides the eye to the heart of operational mastery, making reading a hydraulic diagram not merely deciphering lines but engaging in a language that empowers the craft of maintenance and repair.

0 Comments