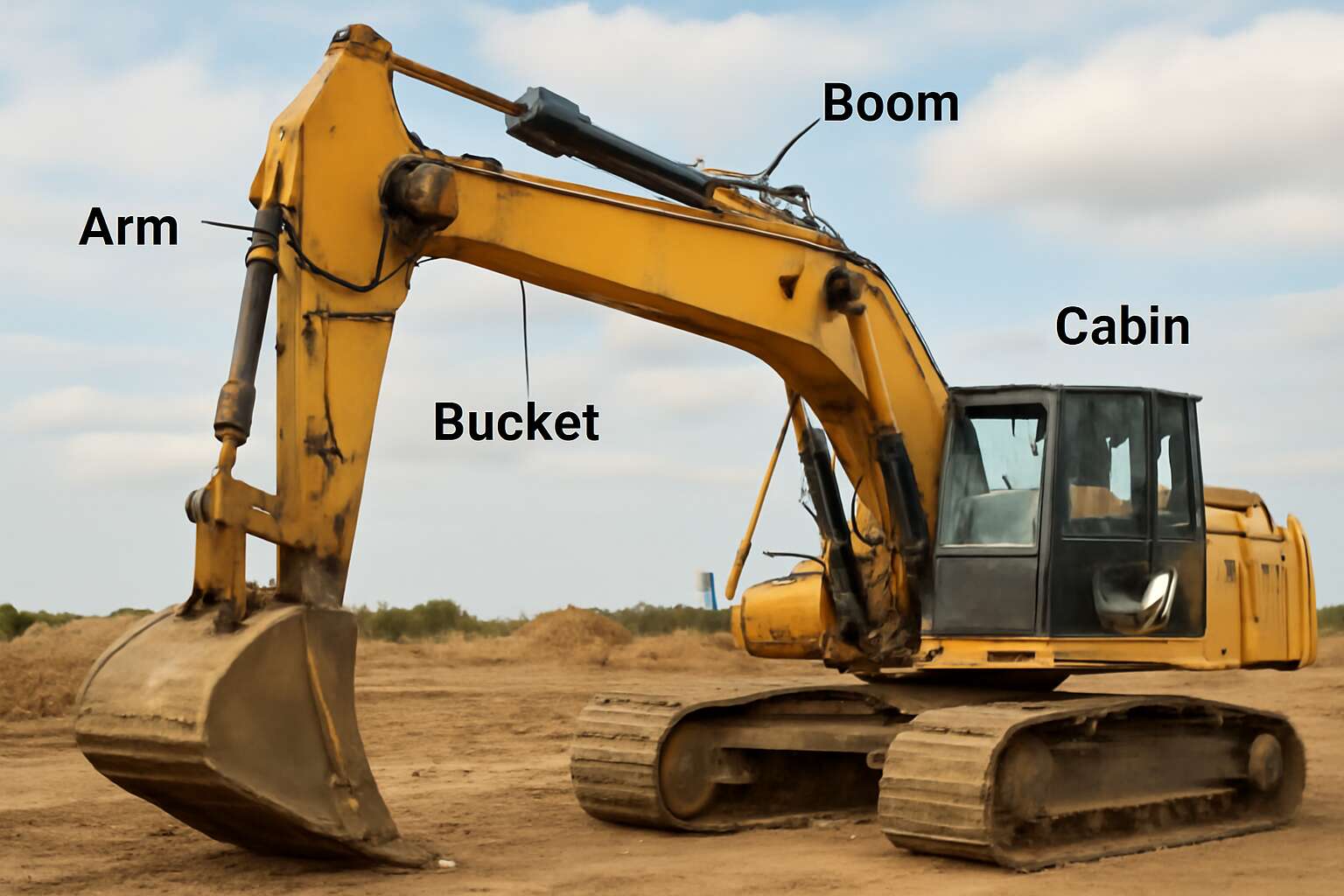

Essential Excavator Components

Main Boom

The main boom of an excavator is often regarded as the backbone of the machine, responsible for providing the essential reach and lifting capacity that define its versatility. This critical excavator parts name is crafted from high-strength steel, designed to withstand the immense forces exerted during heavy-duty operations. Its structural integrity ensures stability, whether you’re hoisting a load or manoeuvring in tight spaces.

Understanding the main boom’s role extends beyond mere terminology; it’s about appreciating its engineering marvel. The boom connects seamlessly with other essential excavator parts name, such as the arm and bucket, creating a harmonious system capable of intricate movements.

In fact, the main boom’s design influences the overall efficiency of the excavator, impacting everything from load capacity to operational precision. When selecting replacement parts or upgrading machinery, paying close attention to the specifications of this vital component is paramount—after all, it’s the primary force behind the excavator’s impressive capabilities.

Stick (Dipper Arm)

The dipper arm, often referred to as the stick, is a vital component in the intricate anatomy of an excavator. It acts as the intermediary between the main boom and the bucket, translating the hydraulic power into precise movements. This part’s engineering precision determines how efficiently an excavator can perform tasks like digging, trenching, or lifting — all essential operations that keep construction projects moving forward.

What makes the dipper arm so fascinating is its ability to extend the reach of the excavator, allowing operators to access hard-to-reach areas with remarkable finesse. Its sturdy construction from high-strength steel ensures durability, even under the most demanding conditions. The connection points, often reinforced with wear-resistant materials, are designed to withstand the repetitive stresses of excavation work.

- Hydraulic cylinder attachments enable smooth, controlled movements.

- Pin joints provide pivotal flexibility for intricate operations.

- Reinforced structural elements prevent fatigue and failure.

Understanding the role of the stick in the broader context of excavator parts name reveals its significance in the overall hydraulic system. When selecting replacement parts or upgrading machinery, recognising the precise specifications of the dipper arm can dramatically influence the operational lifespan and efficiency of your excavator. It’s a testament to the complexity and sophistication embedded within what might seem like simple machinery — a true marvel of modern engineering.

Bucket

The bucket is arguably the most recognisable and essential component within the vast universe of excavator parts name. It’s the tool that transforms raw power into tangible results—digging trenches, lifting debris, or handling materials with relentless precision. Without the bucket, an excavator’s versatility diminishes significantly, making it the cornerstone of every operation. Its design varies depending on the task, from general-purpose buckets to specialised rock or mud buckets, each engineered for durability and efficiency.

What truly sets the bucket apart is its construction from high-strength steel, ensuring resilience against abrasive materials and heavy loads. The cutting edge, often reinforced with a wear-resistant plate, slices through earth and rock alike, maintaining sharpness over countless cycles. The quick coupler system allows for swift attachment changes, boosting productivity without sacrificing safety.

Understanding the inner workings of excavator parts name reveals that the bucket isn’t just a simple scoop. It integrates seamlessly with hydraulic cylinders, which control tilt and dump functions, and the teeth, which grip materials securely. These components work in harmony, ensuring the excavator performs with remarkable finesse and power. Recognising the importance of the bucket within the broader hydraulic system underscores its role in the overall functionality of the machinery—truly a marvel of engineering mastery in modern construction.

Slew Ring

The slew ring, often overlooked in the grand hierarchy of excavator parts name, is the silent fulcrum that underpins the entire machinery’s rotational prowess. This essential component is nothing short of the pivot point for the upper structure, enabling the excavator to pivot smoothly and with unwavering stability. Its robust construction, typically from high-grade steel alloys, withstands relentless stress, resisting both fatigue and corrosion, ensuring longevity under demanding conditions.

Within the vast universe of excavator parts name, the slew ring’s intricacy becomes apparent when you consider its precise assembly and the load it bears. It features an inner and outer race, meticulously machined to facilitate seamless rotation. The inclusion of precision rollers or ball bearings allows for effortless movement, transforming raw torque into controlled, fluid motion. This critical element ensures the excavator’s ability to execute complex manoeuvres with finesse and power, making it a cornerstone of efficient operation.

As part of the overarching hydraulic system, the slew ring’s function extends beyond simple rotation. It’s intricately linked with the slew drive, which transmits rotational force, optimising the machinery’s overall performance. The durability and precision of the slew ring are what ultimately enable the excavator to perform with resilience and versatility in the most challenging environments.

Undercarriage

The undercarriage is often the unsung hero of excavator parts, silently bearing the brunt of each demanding operation. When you think about the backbone of stability and mobility, the undercarriage is where durability meets precision. It’s the critical foundation that keeps the entire machine grounded, even in the most challenging terrains. From rugged construction sites to muddy quarries, the resilience of this assembly determines the efficiency of excavator parts name that you rely on every day.

Within the vast universe of excavator parts name, the undercarriage encompasses several vital components. These include the tracks, rollers, sprockets, and idlers—each performing a unique role in ensuring smooth movement and load distribution. For instance, the tracks provide traction, while the rollers and sprockets facilitate seamless motion over uneven surfaces. The durability of these parts is essential; they are subjected to relentless impact and abrasive forces that threaten longevity. Regular inspection and maintenance of these elements are key to preventing costly downtime and ensuring optimal performance.

Cab and Operator Station

The cab and operator station are often the soul of an excavator, where human skill and machine precision converge in a symphony of power and control. This vital component is meticulously engineered to provide the operator with a sanctuary amidst the chaos of construction sites, ensuring both safety and comfort. Behind the robust exterior lies an intricate array of controls, displays, and ergonomic designs—all essential to the seamless operation of excavator parts name that keep the machine alive and responsive.

Within this sanctuary, the operator interacts with a series of thoughtfully arranged controls, each serving a purpose in manoeuvring the excavator with finesse. From the joystick levers to the advanced instrumentation, every element is crafted to optimise efficiency. The operator station also includes safety features like the seatbelt, emergency stops, and visibility enhancements, all vital to maintaining durability and safety during long hours of demanding work.

Understanding the importance of the cab and operator station elevates your appreciation for the complex network of excavator parts name that make heavy-duty tasks possible. It’s more than just a cockpit; it’s a carefully balanced environment designed to empower those who shape our world with grit and grace.

Hydraulic System Parts

Hydraulic Pump

Within the labyrinth of excavator parts name, the hydraulic system stands as the pulsating heart of operational prowess. At its core lies the hydraulic pump, a marvel of engineering that transforms mechanical energy into the hydraulic power necessary for the machine’s fluid movements. This vital component ensures seamless operation of the boom, arm, and bucket, orchestrating precision with every press of the joystick. Without the hydraulic pump, the entire excavator would stagnate, a lifeless giant unable to perform its formidable tasks.

Understanding the hydraulic system parts is essential for maintaining peak functionality. The hydraulic pump works in tandem with other critical components such as hydraulic valves, cylinders, and hoses. These elements form an intricate network that allows for the controlled application of force, crucial for delicate manoeuvres or heavy-duty excavation work. When one part falters, the entire symphony of excavator parts name falters, risking costly downtime and repairs.

- Hydraulic Cylinders

- Hydraulic Valves

- Hydraulic Hoses

- Oil Filters

Hydraulic Cylinders

Among the myriad of excavator parts name, hydraulic cylinders stand out as the muscle behind the machine’s fluid movements. These robust components convert hydraulic energy into linear force, enabling the boom, arm, and bucket to extend, retract, and manoeuvre with precision. It’s as if they breathe life into the excavator, transforming hydraulic pressure into tangible action that shapes the landscape.

Each hydraulic cylinder consists of a barrel, rod, and end caps, working in perfect harmony to withstand immense pressure and force. When functioning optimally, they deliver smooth, controlled motions that are vital for delicate digging or heavy lifting. A malfunction here can halt entire operations, highlighting the importance of understanding these essential parts within the broader excavator parts name.

In the labyrinth of excavator parts, hydraulic cylinders are complemented by hydraulic valves, hoses, and oil filters, forming an interconnected network of power and control. Whether deploying a simple bucket scoop or performing complex excavation tasks, the hydraulic system’s reliability hinges on these critical components working seamlessly together.

Hydraulic Valves

Within the intricate web of excavator parts name, hydraulic system parts stand as the unseen orchestrators of power and precision. Among these, hydraulic valves emerge as the maestros, controlling the flow of hydraulic fluid with unwavering accuracy. These valves regulate pressure and direction, ensuring each movement — from delicate digging to robust lifting — is executed flawlessly. The subtle yet vital role they play often goes unnoticed until a malfunction causes chaos on the site.

Complementing the valves are hydraulic hoses and oil filters, which form the vital arteries of the hydraulic system. The hoses transport hydraulic fluid under intense pressure, while the filters safeguard the entire system from contaminants that could compromise performance. When functioning in harmony, these parts maintain the excavator’s agility and reliability. Their silent cooperation underscores the importance of understanding the different excavator parts name and how each component contributes to the machine’s formidable capabilities.

- Hydraulic valves

- Hydraulic hoses

- Oil filters

In the shadowy depths of the hydraulic system, each part holds a secret — a story of engineering mastery that keeps the excavator alive and thriving in demanding environments. Recognising the importance of these excavator parts name can be the difference between seamless operation and costly downtime. Every component, from the smallest valve to the largest hose, plays an indispensable role in the grand machinery of excavation.

Hydraulic Hoses

The hydraulic system of an excavator is its unseen powerhouse, quietly orchestrating every movement with precision and force. At the heart of this system lie the hydraulic hoses, often overlooked yet vital components that serve as the arteries transporting pressurised hydraulic fluid. These hoses must withstand extreme pressures and harsh environments, making their durability paramount. Without them, the entire operation risks grinding to a halt.

Understanding the excavator parts name is essential for recognising how these components work in unison. Hydraulic hoses connect key hydraulic components, ensuring fluid flows seamlessly between the hydraulic pump, cylinders, and valves. Proper maintenance of these hoses can prevent costly failures and downtime. In addition, hydraulic oil filters play a crucial role—they trap contaminants that could otherwise damage internal parts and impair performance. When all these parts operate in harmony, the excavator’s agility and reliability are preserved, allowing operators to perform with confidence in even the most demanding conditions.

Next time you see an excavator at work, take a moment to appreciate the complex web of hydraulic hoses and filters—silent sentinels that keep the machine alive. Recognising each excavator parts name within this system is more than just knowledge; it’s the key to understanding the true power behind the machine’s formidable capabilities.

Filters

The hydraulic system is the heartbeat of any excavator, powering its impressive range of movements. Within this intricate network, filters stand as the unsung heroes, diligently protecting vital components from dirt, debris, and contaminants. Without these essential parts—such as hydraulic oil filters—the entire operation risks severe damage and costly downtime. It’s easy to overlook their importance, but in reality, they are the gatekeepers ensuring smooth, reliable performance.

Hydraulic filters are designed to trap impurities before they reach sensitive parts like hydraulic cylinders and valves. This simple act of filtration prolongs the life of the excavator parts name and maintains optimal efficiency. A typical hydraulic filter element might include a mesh or paper medium that captures particles down to microscopic levels. Regular inspection and replacement of these filters are crucial, especially in challenging environments where dirt and dust are abundant.

Understanding the excavator parts name involved in the hydraulic system reveals a web of interdependence. From the hydraulic pump to the various hoses and cylinders, each component works harmoniously to deliver power. By recognising the role of hydraulic oil filters and other vital parts, operators and technicians can better diagnose issues and prevent failures—saving both time and money in the long run.

Engine and Powertrain Components

Engine

At the heart of every powerful excavator lies its engine and powertrain components, the true engines of progress in construction and earthmoving. These parts are responsible for transforming raw fuel into unstoppable force, propelling heavy machinery through the toughest terrains. The engine, often regarded as the soul of the excavator, must be robust and reliable, capable of withstanding the relentless demands of demanding projects.

Complementing the engine are the powertrain components, which include intricate systems like the transmission and drivetrain, ensuring that power is efficiently transferred to the tracks or wheels. Without these vital excavator parts name—such as the engine block, turbocharger, and clutch assembly—the entire operation would grind to a halt. For optimal performance, regular maintenance of these components is essential, keeping the excavator ready for its next adventure beneath the earth or sky.

Cooling System

The cooling system of an excavator is often overlooked, yet it plays a pivotal role in maintaining the longevity and efficiency of critical excavator parts. With the engine working tirelessly to generate power, heat dissipation becomes essential to prevent overheating and ensure consistent performance. This intricate network of radiators, coolant pumps, and thermostats acts as the machine’s thermal regulator, safeguarding vital components from thermal stress.

Without a reliable cooling system, the engine and powertrain components—such as the engine block, turbocharger, and clutch assembly—would be vulnerable to damage. Regular inspection and maintenance of these parts help avoid costly downtime. An effective cooling system keeps the hydraulic pump and hydraulic cylinders operating smoothly, ensuring that every excavator part name functions at peak capacity. For optimal operation, understanding the interconnectedness of these systems is vital for any operator or maintenance professional engaged in earthmoving projects.

Transmission

Amid the symphony of machinery that drives earthmoving excellence, the engine and powertrain components stand as the heartbeat of an excavator. These vital parts, often overshadowed by more visible components, are the silent architects of strength and endurance. The engine itself, a marvel of engineering, transforms fuel into relentless power, propelling the machine forward with unwavering resolve. Supporting this powerhouse is a complex network of transmission parts that translate rotational energy into precise movements, enabling the excavator to perform with finesse.

Within the realm of excavator parts name, the transmission system often includes elements like the hydraulic transmission, planetary gear sets, and clutch assemblies. These components work harmoniously to ensure smooth operation, even under demanding conditions. For those seeking to optimise performance, understanding the intricate relationship between the engine and transmission is paramount. When well-maintained, these parts not only extend the lifespan of the excavator but also elevate its efficiency to new heights.

- Engine Block

- Turbocharger

- Clutch Assembly

- Hydraulic Transmission

- Gear Sets

Every excavator part name, from the smallest bolt to the most robust transmission component, contributes to the resilience and precision of the machine. The harmony of these parts, combined with expert maintenance, transforms raw power into a ballet of controlled force—an ode to human ingenuity and the relentless pursuit of progress.

Drive Motors

When it comes to excavator parts name, few components are as vital yet underappreciated as the drive motors. These powerhouse elements convert hydraulic energy into rotational force, giving the excavator its signature grunt and finesse. Think of them as the machine’s personal trainers—delivering the raw strength needed to lift, dig, and manoeuvre with precision. Without a reliable drive motor, even the most sophisticated hydraulic system is as useful as a chocolate teapot.

Drive motors are often paired with other essential excavator parts name like the hydraulic pump and gear sets, working together seamlessly to ensure smooth operation. A well-maintained drive motor not only prolongs the lifespan of the excavator but also keeps performance on point, especially in demanding environments. From the tiniest bolt to the most complex hydraulic component, every part must work in harmony to turn raw power into a ballet of controlled chaos—proof that even in heavy machinery, finesse is key.

Cooling Fan

In the shadowed realm of heavy machinery, the engine and powertrain components stand as the beating heart of the excavator, pulsing with relentless energy beneath its steel exterior. Among these vital excavator parts name, the cooling fan whispers its silent song—an unsung guardian of thermal balance. Without this seemingly modest component, the engine’s fiery core would succumb to the suffocating embrace of heat, risking catastrophic failure. The cooling fan’s blades, spinning with relentless precision, draw in air to dissipate the oppressive heat generated during gruelling operations.

In this intricate dance of metal and motion, the cooling system’s efficiency hinges on the harmony between the engine and its cooling fan. An optimally functioning cooling fan not only safeguards the engine but also sustains the overall powertrain, ensuring the excavator remains a relentless force in the muddy trenches or towering urban landscapes. It’s a reminder that even within the darkness of heavy-duty machinery, there exists an elegant ballet of cooling and combustion—each part, including the vital cooling fan, playing a crucial role in the machine’s unyielding performance.

Tracks and Undercarriage Parts

Track Chains

In the vast symphony of excavator parts name, the tracks and undercarriage components play a silent but pivotal role. These parts are the foundation of the machine’s stability and mobility, often overlooked yet fundamentally vital. Tracks, often called track chains, serve as the relentless backbone that allows the excavator to traverse rough terrain with unwavering stability. Their durability is tested daily against abrasive surfaces and heavy loads, making them an essential focus for maintenance and replacement.

Undercarriage parts, including rollers, idlers, and sprockets, form the intricate system that supports the track chains. Together, they create a resilient framework that bears the weight of the entire machine. Properly functioning track chains for an excavator not only extend operational life but also optimise performance, ensuring the machine’s efficiency doesn’t falter amidst demanding work conditions. Recognising the significance of each component underscores the importance of understanding the full spectrum of excavator parts name, especially when maintaining such a complex and vital assembly.

Sprockets

Among the myriad excavator parts name that compose this engineering marvel, the sprockets stand out as unsung heroes of the undercarriage. These toothed wheels engage directly with the track chains, acting as the pivotal link that transfers engine power into the movement of the machine. Without sprockets, the entire system risks slipping into chaos, or worse, complete immobilisation. Their design is crucial—precise teeth geometry ensures optimal grip and minimal wear, a delicate dance of robustness and finesse.

Complementing the sprockets are other essential components of the tracks and undercarriage parts, such as rollers and idlers, which keep the track chain aligned and smoothly running over uneven terrain. When these parts work in harmonious synchrony, the excavator’s stability and mobility are preserved, even on the most treacherous sites. It is this intricate ensemble that underscores the importance of understanding the full spectrum of excavator parts name, especially when maintenance is due or replacements are needed to prevent costly downtimes. After all, a well-maintained track system is the backbone of relentless performance in construction and earthmoving operations.

Idlers

Among the vital excavator parts name that often escape the spotlight are the idlers—silent guardians of the track system’s integrity. These robust components sit at the end of the undercarriage, guiding and tensioning the track chains with relentless precision. Without properly functioning idlers, the track would lose alignment, leading to uneven wear or catastrophic failure. Their design must withstand harsh conditions, absorbing shocks and maintaining consistent tension to ensure smooth operation even on rugged terrain.

The health of an excavator’s track system hinges on the harmonious interaction of these parts. When in optimal condition, idlers work seamlessly with rollers, sprockets, and track chains, creating a resilient undercarriage that endures the brutality of heavy-duty work. Recognising the importance of these seemingly humble parts underscores why diligent maintenance of excavator parts name, like the idlers, is fundamental to preventing costly downtime and prolonging the lifespan of machinery.

Rolling Wheels

Tracks and undercarriage parts are the unsung heroes of any powerful excavator, transforming raw force into precise movement across rugged terrain. These components, including rolling wheels and track chains, form the backbone of the machine’s stability and mobility. Without them, even the most advanced excavator parts name would be rendered useless—imagine a giant beast stranded in the mud! The rolling wheels, often called track rollers, distribute weight evenly, absorbing shocks and maintaining smooth operation under heavy loads.

To truly appreciate the complexity of excavator parts name, consider the interplay of sprockets, rollers, and track chains. They work in harmony to create a resilient undercarriage that can withstand the relentless demands of construction sites. Here’s a quick overview of these vital parts:

- Sprockets – drive the track chain and transmit power

- Track rollers – support the weight and guide the track

- Idlers – maintain proper tension and alignment

Each element plays a crucial role in ensuring the excavator moves seamlessly, even when faced with the harshest conditions. When these parts function optimally, the machine’s performance is nothing short of extraordinary—delivering reliability, durability, and efficiency in every dig.

Track Rails

The backbone of any formidable excavator lies beneath the surface—where the tracks and undercarriage parts form an intricate, almost poetic, system of survival. Among these, track rails stand as silent sentinels, anchoring the machine’s relentless pursuit of progress across unforgiving terrain. They are the rigid guides that sustain the weight and facilitate the precise movement of the entire undercarriage assembly. To appreciate the intricacies of excavator parts name, one must recognise how vital these components are to overall stability.

Track rails work in tandem with other elements like track chains and sprockets, creating a resilient loop of motion and support. When functioning optimally, they absorb shocks, distribute loads evenly, and keep the excavator rooted firmly in its environment. This symphony of parts ensures the machine not only moves seamlessly but endures the brutal realities of construction work. Though often overlooked, the strength and durability of track rails are what transform raw power into purposeful movement—without them, even the most advanced excavator parts name would be rendered inert.

Electrical Components

Battery

Electrical components, especially the battery, are the backbone of an excavator’s operational efficiency. Without a reliable excavator battery, even the most robust excavator parts name like hydraulic pumps or engine components can become useless. A high-quality battery ensures consistent power supply, enabling the machine to start smoothly and operate without interruptions. It also plays a vital role in powering other electrical systems within the excavator, from lights to control panels.

Understanding the significance of the excavator battery is crucial for maintenance and troubleshooting. Modern excavator parts name now include advanced battery systems designed to withstand harsh conditions and provide longer service life. Regular inspection and timely replacement of the battery can prevent costly downtime and extend the lifespan of your machinery. After all, in the world of heavy equipment, reliable electrical components are not just a convenience—they are an essential part of keeping the excavator running efficiently.

- Battery terminals

- Voltage regulator

- Starter motor

- Alternator

Lighting System

The electrical components of an excavator are the unsung heroes behind its smooth operation. Among them, the lighting system is vital for safety and visibility, especially during low-light conditions or at night. Proper illumination ensures that operators can see their surroundings clearly, reducing the risk of accidents. The lighting system includes essential parts like work lights, signal lights, and internal cab lighting, all designed to withstand harsh construction environments.

In addition to lighting, other electrical components such as the voltage regulator, starter motor, and alternator work together to maintain optimal power flow. These parts are crucial for ensuring consistent electrical supply to all excavator parts name, preventing unexpected downtime. Well-maintained electrical systems not only boost efficiency but also extend the lifespan of the excavator.

Understanding the role of electrical components in the lighting system and beyond helps operators and maintenance teams keep the machinery running reliably. When electrical issues arise, quick diagnosis and replacement of faulty parts like the electrical wiring harness or connectors can save time and money. Ultimately, a robust electrical system is the backbone of an excavator’s operational success!

Control Panel

The control panel of an excavator is the nerve centre that orchestrates the machine’s complex symphony of functions. It’s where all the electrical components converge, providing operators with seamless access to vital systems and diagnostics. This crucial excavator parts name acts as the interface between human control and machine performance, ensuring precision and safety during operation.

Within the control panel, numerous intricate parts work together—fuses, relays, circuit breakers, and gauges—each playing a pivotal role in maintaining electrical harmony. An efficient control panel not only simplifies troubleshooting but also enhances overall reliability, especially in demanding construction environments. When electrical issues arise, quick identification of faulty components such as switches or wiring harnesses can prevent costly downtime and keep projects on schedule.

Understanding the significance of the control panel in the broader context of excavator parts name reveals why consistent maintenance of this vital component is essential. It’s the command hub that ensures all other excavator parts name function optimally, from hydraulic systems to lighting, ultimately enabling operators to work with confidence and precision.

Sensors

Electrical components and sensors form the silent sentinels of an excavator, diligently ensuring every movement is precise and responsive. These unseen heroes translate complex signals into actionable commands, transforming operator intent into machine mastery. The heartbeat of this system lies in sophisticated sensors that continuously monitor vital parameters—temperature, pressure, and position—allowing the excavator to adapt seamlessly to dynamic conditions.

Within this intricate web of excavator parts name, sensors such as proximity sensors, load sensors, and temperature sensors play pivotal roles. They detect anomalies and relay real-time data to the control panel, facilitating instant adjustments. For example, load sensors can prevent overexertion of hydraulic cylinders, safeguarding the machine from damage while optimising performance. This harmony between electrical components and sensors not only enhances safety but also maximises operational efficiency on demanding sites.

- Proximity sensors for arm and boom positioning

- Temperature sensors safeguarding hydraulic and engine systems

- Pressure sensors monitoring hydraulic fluid dynamics

Understanding these electrical components and sensors deepens appreciation for the complexity behind every excavator parts name. They are the quiet guardians that enable precision, durability, and longevity in the relentless world of heavy-duty construction. When every second counts on-site, these technological marvels ensure that the excavator operates at peak performance, turning raw power into refined craftsmanship.

Wiring Harness

Behind the scenes of every mighty excavator, where raw power meets intricate engineering, lies a complex network of electrical components that keep the machine humming with precision. Central to this web is the wiring harness — the unseen yet vital backbone connecting countless excavator parts name, from sensors to control panels. Imagine a labyrinth of insulated cables, seamlessly transmitting signals that orchestrate every movement with finesse. It’s as if each wire whispers commands to the machine’s heart, ensuring synchronisation and operational harmony.

The wiring harness is designed to endure the gruelling conditions of construction sites, resisting dust, moisture, and vibration. It acts as the conduit for electrical flow, linking vital components such as the control panel, sensors, and actuators. Its organised architecture simplifies maintenance and reduces downtime, safeguarding the excavator’s longevity. When every second counts, this vital component ensures that power and data flow unhindered, translating complex commands into tangible results. Truly, the wiring harness is the silent conductor of the excavator’s symphony of strength and precision.

Other Important Excavator Parts

Counterweight

Amidst the shadowed labyrinth of excavator parts name, the counterweight emerges as a silent sentinel—an essential guardian against the chaos of imbalance. This heavy, often overlooked component ensures stability during the relentless dance of excavation, holding the machine steady amidst turbulent forces. Without it, the entire structure risks tumbling into ruin, a fragile titan teetering on the edge of catastrophe.

In the grand architecture of excavator parts name, the counterweight’s purpose is both simple and profound. It counteracts the weight of the boom, stick, and load, maintaining equilibrium in a world where chaos lurks just beneath the surface. Its design varies—sometimes a cast iron mass, other times a modular assembly—yet its role remains unwavering. For those seeking to understand the full scope of excavator parts name, recognising the significance of this weighty guardian is vital to grasping the machine’s delicate balance.

Swing Gear

Amidst the intricate web of excavator parts name, the swing gear is often the unsung hero—cranking like a well-oiled ballet dancer, allowing the upper structure to pivot smoothly on its axis. This vital component transmits rotational force from the slew ring to the cab, enabling precise manoeuvres that would make even the most graceful ballerina jealous. Without a dependable swing gear, the entire operation risks becoming a clumsy spectacle rather than a symphony of efficiency.

Think of the swing gear as the conductor in the orchestra of excavator parts name—coordinating the movement of the upper structure with finesse. Its design typically involves durable gears and bearings, engineered to withstand the relentless torque and dirt of construction sites. For those exploring the depths of excavator parts name, recognising the importance of the swing gear is crucial—this component keeps the machine spinning seamlessly, even under the most demanding conditions.

Axles

Beyond the well-known components, the crucial role of axles in excavator parts name often goes unnoticed—yet they form the backbone of machine mobility and stability. These robust shafts are designed to transfer power from the transmission to the wheels or tracks, ensuring smooth movement across rugged terrains. Without dependable axles, even the most sophisticated excavator parts name would be rendered useless, trapped in a cycle of instability and inefficiency.

In the intricate machinery of an excavator, axles work tirelessly to support the weight and facilitate precise control. Their durability is tested daily against extreme forces and dirt-laden environments. For those delving into the depths of excavator parts name, recognising the importance of axles is essential—these components keep the machine grounded, allowing operators to execute complex tasks with unwavering confidence.

Pins and Bushings

Among the lesser-celebrated yet vital components in excavator parts name are pins and bushings. These unassuming parts are the silent guardians of machine integrity, holding crucial moving parts together with precision. Without high-quality pins and bushings, even the most advanced excavator parts name would struggle to perform reliably over time.

Pins serve as pivotal connectors, allowing articulated movement of the boom, arm, and bucket. Meanwhile, bushings act as protective sleeves, reducing wear and tear caused by repetitive motion. The durability of these components directly impacts the lifespan of your excavator. For those seeking a deeper understanding of excavator parts name, recognising the importance of pins and bushings is essential—these are the unsung heroes ensuring smooth operation in every task.

- Proper lubrication

- Material quality

- Alignment precision

In demanding environments, where dirt and debris threaten to cause havoc, these parts are subjected to relentless stress. The right pins and bushings can turn a potential failure point into a model of resilience, allowing your excavator to perform with unwavering confidence day after day. When exploring excavator parts name, never overlook these critical links in the chain of operation—without them, stability and efficiency are impossible to maintain.

Major Attachments

Within the intricate tapestry of excavator parts name, a constellation of major attachments plays a pivotal role in the machine’s symphony of power and precision. These components, often overlooked in favour of more glamorous elements, are the backbone of operational excellence. From the formidable boom to the versatile quick coupler, each part bears a unique signature—an essential hallmark of robustness and adaptability.

Imagine the hydraulic quick coupler as the maestro’s baton, seamlessly connecting diverse attachments and transforming the excavator’s capabilities at a moment’s notice. The heavy-duty counterweight, on the other hand, acts as the stabilising anchor, preventing the entire structure from succumbing to the forces of leverage and gravity. These major attachments are not merely add-ons but vital organs in the body of the excavator, enabling it to conquer a multitude of tasks with unwavering resilience.

In the realm of excavator parts name, the importance of these major attachments cannot be overstated. They serve as the bridge between raw power and precise execution, ensuring that every dig, lift, and manoeuvre is executed with finesse and control. As the silent sentinels of heavy machinery, these parts forge the path to operational mastery and longevity.

0 Comments